PP&S is now OTC! To streamline your ordering process and improve your customer experience we are redirecting you to OTCindustrial.com

Headquartered in Charlotte, NC, PP&S is a regional distributor of rotating and process equipment serving industrial, municipal and energy markets throughout the Southeast. In addition to a substantial portfolio of OEM equipment and parts, PP&S offers a comprehensive suite of individual and integrated services that support systems design, performance optimization, equipment longevity and inventory management, as well as many process and management facilitation solutions.

PP&S is now OTC! Learn how OTC can help support your business.

Phone: 704-588-6250

After Hours Emergency Service: 800-417-6250

Locations:

3149 Dublin Lane

Bessemer, AL 35022

3925 Stuart Andrew Blvd.

Charlotte, NC 28217

Services

Products

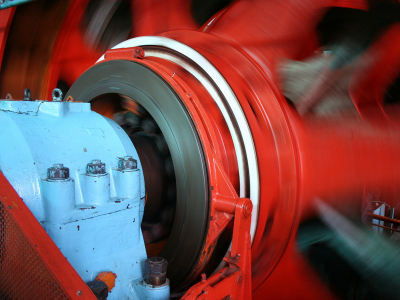

Industrial Equipment

PP&S brings over 300 years combined technical and applications experience to your industrial processing challenge. In addition to ongoing training, most PP&S associates have accrued over 20 years hands-on expertise from the OEM, manufacturing and supply chain sides of the business. So we’re uniquely qualified to anticipate issues, troubleshoot problems and partner in achieving your immediate and long-term goals.

Environmental Equipment

The PP&S Environmental division has focused exclusively on the needs of municipal, building and environmental customers for over 25 years. So our specialists bring a wealth of experience in devising total lowest cost solutions for water supply and transfer, wastewater, stormwater and industrial wastewater processes including: Conveyance, Secondary Treatment, Advanced Treatment, Solids Processing, Solids Dewatering, Process Control, and Distribution.

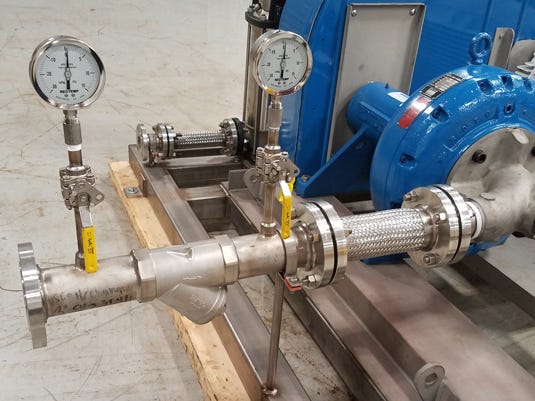

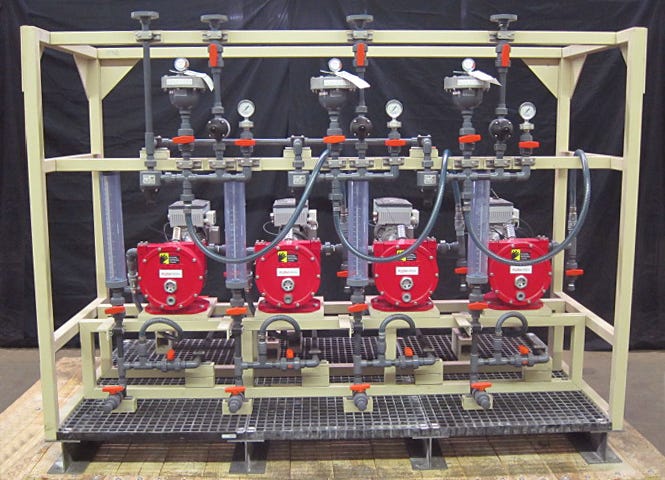

Packaged Systems

With tighter schedules and budgets, organizations are increasingly opting for the cost-effectiveness and reliability of pre-designed, configured and tested skid systems. At PP&S, our engineering services team has over 400 years combined experience in mechanical/electrical design and systems integration for a broad range of process applications and manufacturing environments. And we put that know-how to work in assuring your custom packaged skid system is expertly designed, fabricated and tested to perform seamlessly once it arrives at your facility.

Inventory

With tighter schedules and budgets, organizations are increasingly opting for the cost-effectiveness and reliability of pre-designed, configured and tested skid systems. At PP&S, our engineering services team has over 400 years combined experience in mechanical/electrical design and systems integration for a broad range of process applications and manufacturing environments. And we put that know-how to work in assuring your custom packaged skid system is expertly designed, fabricated and tested to perform seamlessly once it arrives at your facility.